Millwright Average Salary in USA, 2026

Millwright salaries in the United States are a critical metric for skilled trades professionals navigating the 2026 job market. What is the true earning potential for a Millwright this year, and how do factors like location, experience, and industry specialization impact pay? This comprehensive analysis provides a detailed breakdown of the average Millwright salary, state-by-state comparisons, and key insights into the career path. Understanding these figures is essential for both job seekers negotiating offers and employers aiming to attract top talent in a competitive field.

What Is the National Average Salary for a Millwright in 2026?

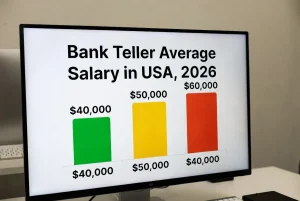

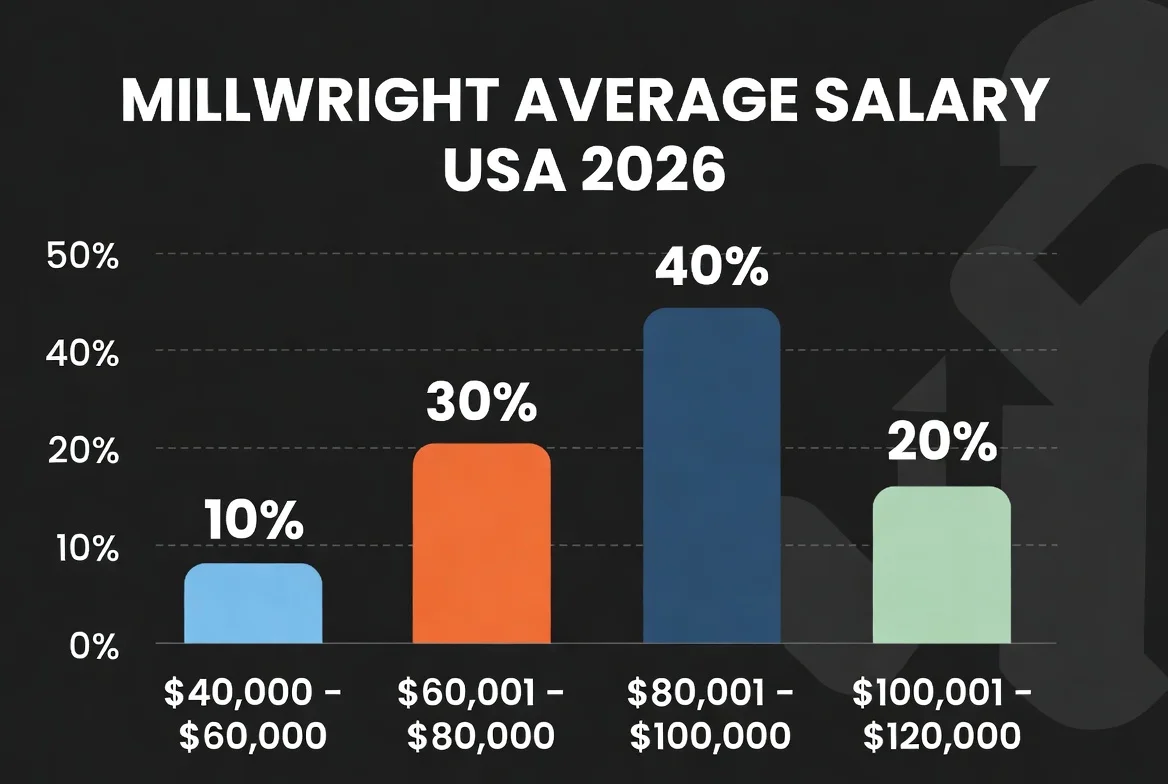

How much can a Millwright expect to earn annually in the current economic climate? Based on aggregated data from 6,635 salaries, the average Millwright salary in the United States for 2026 is $63,895 per year. When broken down hourly, this equates to approximately $32.34 per hour. What is the difference between entry-level and experienced pay? Entry-level positions typically start around $54,600 per year, while the most experienced and highly skilled Millwrights can command salaries up to $73,100 per year. This salary range reflects the value placed on practical expertise, technical certification, and hands-on experience in installing, maintaining, and repairing industrial machinery.

Which States Offer the Highest Millwright Salaries in 2026?

Location is a primary driver of wage variation. How much does geography impact a Millwright’s paycheck? The data reveals significant disparities, with top-paying states offering premiums well above the national median.

Top 5 Highest-Paying States for Millwrights:

-

Delaware: $71,949

-

Washington: $68,250

-

California: $66,560

-

Oregon: $65,520

-

Connecticut: $63,024

What are the reasons for these higher wages? States like Delaware and Washington often have strong union presence, high costs of living, and concentrated industries requiring complex machinery, such as aerospace, heavy manufacturing, and energy production. Which states fall below the national average? Southern and some Midwestern states, such as Maine ($49,920), Vermont ($51,688), and Mississippi ($52,000), report lower average salaries, often correlating with regional industry profiles and living costs.

What Factors Influence a Millwright’s Earning Potential?

Beyond location, several key factors determine salary. What is the best way for a Millwright to increase their income?

-

Experience & Seniority: This is the most significant factor. Progression from apprentice to journeyman to master millwright comes with substantial pay increases.

-

Industry Specialization: Millwrights in specialized sectors like aerospace manufacturing, power generation, or automotive plants often earn more than those in general manufacturing.

-

Union Membership: Unionized millwrights typically have higher wages, better benefits, and more structured pay scales.

-

Certifications & Skills: Welding certifications (AWS), laser alignment expertise, proficiency with CNC machinery, and PLC knowledge can command premium pay.

-

Overtime & Travel: Many millwright roles, especially in construction and field service, offer significant overtime pay and per diems for travel.

How fast can a Millwright’s salary grow? With consistent skill development and certification, a millwright can move from an entry-level wage to the top of the pay scale within 5-10 years.

What Are the Typical Job Duties of a Millwright?

Understanding the salary requires knowing the role. What does a Millwright do on a daily basis? Their work is highly technical and physically demanding, involving the installation, dismantling, maintenance, and repair of industrial machines and heavy equipment. Key duties include:

-

Reading technical diagrams and blueprints.

-

Aligning and leveling machinery with precision tools (lasers, dial indicators).

-

Assembling and installing new equipment.

-

Diagnosing mechanical problems and performing repairs.

-

Welding and metal fabrication for parts and components.

-

Conducting preventive maintenance schedules.

What are the pros and cons of this career? Pros include high job security, competitive pay without a four-year degree, and engaging hands-on work. Cons can involve working in noisy environments, physical strain, potential for injury, and occasional travel or irregular hours.

How Does Millwright Pay Compare to Related Trades?

Is a Millwright salary competitive within the skilled trades ecosystem? What is the difference between a Millwright and similar roles?

| Related Job Title | Average Annual Salary (2026) | Key Difference from Millwright |

|---|---|---|

| Rig Manager | $100,000 | Supervisory role overseeing rigging operations, higher responsibility. |

| Millwright | $63,895 | Focus on installation, alignment, and repair of stationary industrial machinery. |

| Maintenance Mechanic | $54,600 | Broader, often less specialized maintenance of plant equipment. |

| Industrial Mechanic | ~$58,000 | Very similar to millwright; terms are often used interchangeably. |

| Field Service Technician | $52,686 | Focus on troubleshooting and repairing equipment at customer sites. |

| Iron Worker | $42,380 | Focus on structural steel for construction, not precision machinery. |

This comparison shows that Millwrights occupy a well-compensated, specialized niche within the mechanical trades.

What Is the Job Outlook for Millwrights in 2026 and Beyond?

Is it worth pursuing a career as a Millwright in the current economy? The outlook remains stable. As existing industrial machinery ages and new, complex automation is integrated, the need for skilled professionals to install and maintain this equipment persists. How many jobs are projected? While automation may slow growth in some areas, retirements of an aging workforce are expected to create consistent demand for new millwrights through 2026 and beyond. Sectors like renewable energy and advanced manufacturing are particularly strong growth areas.

How Can You Become a Millwright and Advance Your Career?

What is the best way to enter this field and maximize earning potential? The most common path is a formal apprenticeship program, typically lasting 3-4 years, which combines paid on-the-job training with classroom instruction. These programs are often sponsored by unions, contractor associations, or individual employers. Should you seek certifications? Pursuing additional certifications in welding, alignment, or specific machinery brands is one of the top strategies for career advancement and salary negotiation.

Frequently Asked Questions (FAQs)

1. What is the average starting salary for a Millwright apprentice?

Apprentice salaries typically start as a percentage of the journeyman rate, often between 40-60%. Based on the national entry-level figure of $54,600, an apprentice might start between $22,000 and $33,000 annually, with increases at each stage of the program.

2. Do Millwrights get paid overtime?

Yes, overtime is very common, especially during equipment installations, shutdowns, or emergency repairs. Many millwrights significantly increase their annual earnings through overtime pay at time-and-a-half or double-time rates.

3. What is the difference between a Millwright and an Industrial Mechanic?

The terms are often used interchangeably. However, “Millwright” traditionally implies a stronger focus on the original installation and alignment of machinery, while “Industrial Mechanic” may emphasize ongoing maintenance and repair. In practice, job duties heavily overlap.

4. Which industries pay Millwrights the most?

In 2026, the highest paying industries tend to be aerospace product and parts manufacturing, pharmaceutical manufacturing, oil and gas extraction, power generation, and motor vehicle manufacturing.

5. How does union membership affect a Millwright’s salary?

Union membership typically results in higher wages, superior benefits (healthcare, pension), and more structured pay scales based on experience. Collective bargaining agreements set clear standards for compensation and working conditions.

6. Are Millwrights in demand?

Yes, demand remains steady. The need to maintain aging infrastructure and install new automated equipment, coupled with a wave of retirements, ensures ongoing opportunities for skilled millwrights.

7. What skills are most important for a high-paying Millwright job?

Beyond mechanical aptitude, skills that command top dollar include precision laser alignment, advanced welding (especially TIG), CNC machinery knowledge, understanding of hydraulic and pneumatic systems, and basic PLC troubleshooting.

Disclaimer: The salary data presented for the Millwright profession is based on aggregated sources and is intended for informational and guidance purposes only as of 2026. Actual salaries can vary widely based on individual experience, specific employer, exact location, union contracts, and current economic conditions. This information should not be used as the sole basis for financial or career decisions.

Keywords: millwright average salary, millwright salary 2026, how much does a millwright make, millwright hourly wage, industrial mechanic salary, millwright apprentice pay, highest paying states for millwrights, millwright job outlook, millwright vs mechanic, skilled trades salary